The heart of our business philosophy

A dedicated team at your service

On a daily basis, Vincent Carpentier and his team of flavourists improve, modify, adapt and design new flavours suited to the new market trends and specific customers’ requests.

Our R&D laboratories are well endowed with chromatography and spectrometry materials, soxlhet, reactors, spectro-photometer, …which allow us to carry out different studies & analysis on new raw materials and flavours.

The pilot homogenizer and spray dryer are used for testing and validating new flavour formulations.

Being classified "ST2", our pilot spray dryer allows us to work with concentrated key base. Our industrial spray dryer is also "ST2" classified, hence we can produce stronger and highly concentrated spray dried flavours.

Regarding liquid flavours developments, the flavourist ‘s laboratory trials are immediately processed into the Roxane weighing robot (high accuracy dispensing automated systems), for evaluation and validation before registration in our flavour library.

Regular and active technology intelligence carried out by our flavourists allows them the use and knowledge of new raw materials, techniques and processes.

At Expressions Aromatiques, fundamental research and applied research are jointly used in the R&D teamwork. This is how, for example, after 4 years of investigation and tests, we were able to register a patent for a new process of encapsulation by extrusion.

At Expressions Aromatiques, Research and Development also means:

Quality Control at every stage of development

In order to avert any risk of contamination and guarantee the quality of the finished product, we apply a systematic approach to quality control at every stage of the manufacturing process; from checks on raw materials, through to semi-finished goods (bases, solutions and key bases) right up until the finished product.

An experienced and informed legislative department

Rigorous sensory analysis

In our new laboratories we use standardised tasting booths to guarantee a neutral atmosphere and environment, thus allowing our sensory evaluators to test our flavours and products in the most optimal conditions.

Our internal sensory panel is made up of initiated and expert sensory assessors, selected based on the demonstrated sensitivity of their sensory perceptions, their continuous training and their experience. Our sensory panel is able to conduct a various number of sensorial tests:

– Hedonic tests: these are tests that focus on the concept of pleasure and feelings;

– Discrimination tests or comparison tests: descriptive tests that are used to achieve an effective description of the products analysed and to obtain the “sensory profile” of a product, triangle test, ranking test, comparison test…

Our training and monitoring process follow the requirements of the AFNOR standards.

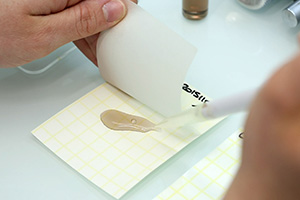

Applications Laboratory

Flavours are evaluated and tested in both sweet and savoury applications, in realistic conditions.

New recipes are created, developed and improved every day, allowing us to try out our various flavouring creations in a host of different ways.

Sampling Service

Our teams operate a highly responsive preparation and dispatch system, guaranteeing you professional quality product samples delivered quickly and securely.